{This article was written by Budgie a number of years ago and published elsewhere. It was part of his ‘Tackle Workshop’ series. Digital cameras have come a long way since then, so we hope to change some of the photographs in the future.

Budgie will be writing some new material of this variety for us soon. If you’ve got a question about making, fixing or servicing any item of fishing tackle, please email it to info@anglersnet.co.uk and we’ll see if we can answer it. We won’t be able to answer all questions and, obviously, it won’t be an instant service. If you need a ‘quick fix’, you will be better off posting to our forums, or getting us to do it for you by clicking here and filling in the form.

If you see a term underlined in this article, this means that it is linked. Click on it to be taken to examples of that product for sale -Ed}

A reader from the USA recently contacted Tackle Workshop asking how to make a Carp “Springer” type indicator. The Springer is a fairly recent arrival on the carp indicator scene. It is best used to show drop back bites, especially at range. This is a simple project and it uses some of the DIY components that we have already shown on previous projects. The main components required you may already have, but if not, they are easily found in your local tackle shop. As I always say, be careful if you have to buy too many of the bits, as this can push the cost up over the cost of a ready made one!

The easiest way to make the arm of the springer is to take an old screw in type quiver tip. These come in a variety of different test curves, usually expressed in ounces. The strength you choose will obviously be dictated by the range that you intend to fish. The greater the range, the greater the strength required. If you cannot get the quiver tip, a length of glass/carbon such as a “flick tip” from a pole or maybe the easiest for you in the USA, a length of fibre glass dowel from a model shop will suffice. Unless you are using the quiver tip (which will all ready have one), you will need to attach an eye on to the end of the arm. The wire quiver tip type eyes are ideal, but if you wish to save money you can use the cut off eye of a safety pin. This can be attached by a simple whipping or, if you have not yet mastered this art, fix it in place with a dab of super glue and length of rig tube.

To make the bobbin to fit on the end of the arm, simply refer back to the “Hanger” indicator article previously shown. This makes an ideal head. It is, however, best to use the adjustable line clip in this situation. The easiest way to assemble is to first tie a length of line (I like 40lb Amnesia) to the line clip and thread it through the hanger. Next take a split ring and clip it on to the eye of the quiver tip/arm. Thread the line through the split ring and back through the hanger, as shown in the photograph. Pull every thing tight and insert the clip into the hanger. Cut off any spare line.

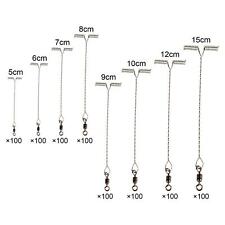

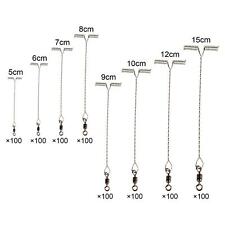

To attach the swinger arm to the buzzer bar/rod rest, you can use either the perspex tab or the hockey sticks as, once again, shown in the Hanger article. For this job, the plastic Solar hockey sticks are best as they are a lot cheaper and the easiest method is to glue (Araldite or a similar epoxy resin type glue) the arm in. Even cheaper is the tab; this is best made as follows. Take a 1” wide strip of perspex or metal of around ¼” thick and mark it out as shown. Drill out a 10mm hole, cut of the waste and round of the corners. Paint if required. If using the tab method, ensure that you drill the hole that will take the arm at the correct angle. This is once again dictated by the strength of the arm. The easiest way to get this angle is to set up your rod on the rest with the tab attached. Attach the head to the line and bend the arm, so that it sits correctly. Once the correct angle has been established, mark this angle on the side of the tab and drill the hole at the same angle.

So there you have it. Even if you have to buy some of the materials, it should still cost a lot less than in the shops and it’s fun to make. As you will now have started to notice, I use the same types of material for many of the projects. Before starting on a project, always look around to see what you already have as many different things can be used to achieve the same result. This is how you will really save the pennies!